Last year, China retired a total of more than 580,000 tons of lithium batteries. By next year, that number is expected to be close to 800,000 tons. Where do all those lithium batteries go? How to deal with it?

With the replacement of new energy vehicles, lithium batteries as their core components will also usher in a large-scale "retirement tide". Last year, China retired more than 580,000 tons of lithium batteries. By next year, that number is expected to be close to 800,000 tons. Where do all those lithium batteries go? How to deal with it?

According to the national standard for new energy vehicles, the performance of the power battery will decay with the increase of charging times, and when the battery capacity decays to less than 80% of the rated capacity, it is no longer suitable for electric vehicles, and a qualified regular power battery recycling enterprise is required for recycling.

Why the emphasis on formal enterprises? Experts say electric car batteries weigh hundreds of kilograms. When the vehicle is scrapped, the lithium hexafluorophosphate in the battery is easily hydrolyzed in the air environment to produce harmful substances such as phosphorus pentafluoride and hydrogen fluoride, which will cause environmental pollution if not treated well. Moreover, decommissioned lithium batteries actually have a high utilization value, at present, there are two modes of lithium battery recycling: echelon utilization and recovery of raw materials. The former is to disassemble and reassemble the battery, and apply it to the field such as energy storage, which does not require high battery energy density; The latter is to extract expensive metal materials such as cobalt, nickel and lithium from discarded batteries and recycle them into new batteries.

With the continuous growth of China‘s new energy vehicle industry, the new energy vehicle power battery recycling industry has grown rapidly.

Zhang Ying, president of the Automotive recycling Industry Development Committee of China Asian Economic Development Association: At present, the recycling of power batteries is a white list of enterprises, and it is also divided into echelon utilization enterprises, recycling enterprises, including the recycling outlets built by the main engine factory. From the current point of view, there are more than 15,000 recycling outlets in the country, which can basically cover more than 85% of the entire market field of new energy vehicles.

Recycling and dismantling lithium batteries of new energy vehicles "regain a new life"

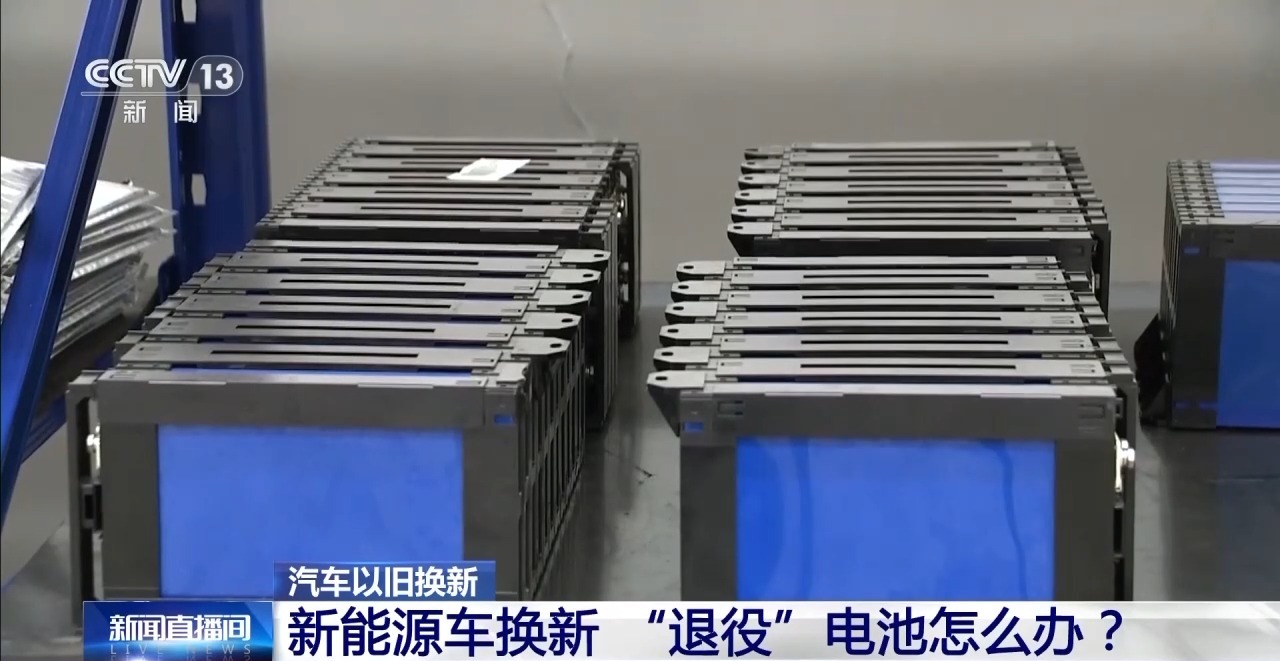

In the world‘s first echelon utilization and recycling "zero carbon" factory in Zhejiang Province, in this battery pack flexible automatic dismantling line, end-of-life batteries are dismantled and extracted valuable renewable resources, and finally recycled into new battery material production, where 65,000 tons of waste battery materials can be processed every year.

This power battery recycling company in Foshan, Guangdong province, has professional processing equipment that can chemically extract recycled materials after dismantling power batteries.

Ou Yannan, head of a power battery recycling company: the recovery rate of nickel, cobalt and manganese is 99.6%, the recovery rate of lithium is 91%, and the positive electrode material of the power battery is re-prepared and applied to the new battery, which truly realizes where the battery resources come from.

According to the statistics of the China Renewable Resources Recycling Association, the net increase of vehicle scrap in 2023 is 7.56 million, an increase of 32%, and the standardized recycling and utilization of used household appliances is about 93 million units, with a weight of about 4.4 million tons. More than 200 million pieces of furniture were recycled. Among them, the recycling and utilization of 10 major renewable resources, including scrap steel, scrap non-ferrous metals and waste plastics, amounted to about 392 million tons, which continued to play a prominent role in supporting national resource security.

Source: CCTV News client

Author: Gong Lihui

Responsible Editor: Lin Yin