Foreword: Since its inception, lithium batteries have been favored by 3C digital, power tools and other industries due to their advantages of high energy density, high voltage, environmental protection, long life and fast charging, and their contribution to the new energy vehicle industry is particularly prominent. . As the world‘s energy crisis and environmental protection issues become increasingly prominent, the lithium battery industry, which provides power sources for new energy vehicles, has huge market potential and is an important part of national strategic development.

Basic introduction of PACK battery pack:

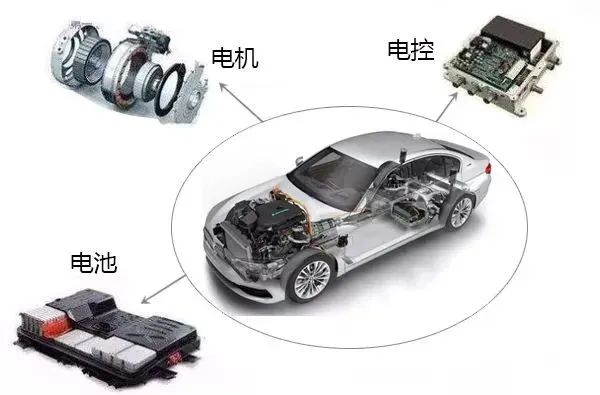

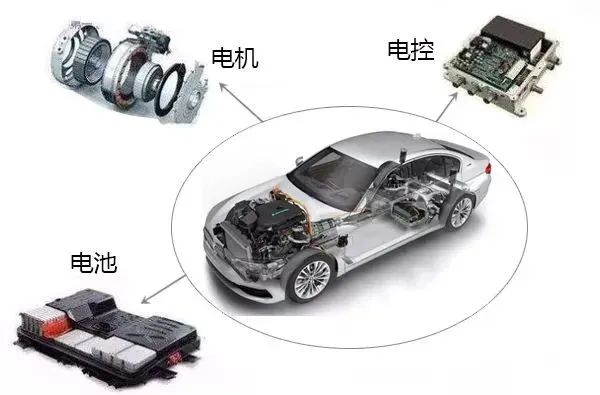

New energy vehicle three-electric system

New energy vehicle three-electric system The battery pack (PACK) is integrated with the chassis

Classification of PACK battery packs:

First of all, it is necessary to understand the general distinction between lithium battery cells, lithium battery modules and lithium battery packs:

Battery cell (cell): the most basic element that constitutes the battery pack and battery pack, generally the voltage that can be provided is between 3v-4v;

Battery pack (Batteries): a collection of multiple monomers to form a single physical module, providing higher voltage and capacity;

Battery pack (pack): It is generally composed of multiple battery packs. At the same time, a battery management system (bms) is also added, which is the final product provided by the battery factory to the user.

The composition and classification of PACK:

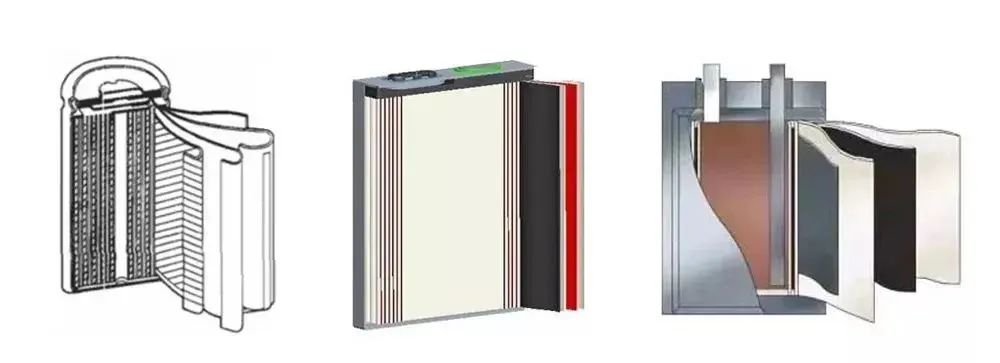

As the core component of PACK, batteries are currently classified into three main categories according to the shape of the batteries: square shells, cylinders, and soft packs (polymer batteries). The positive and negative electrodes are encapsulated into corresponding casings in different ways.

.png) Left cylindrical winding Middle-square winding Right-square stacking

Left cylindrical winding Middle-square winding Right-square stacking

Left-cylindrical cell Middle-square shell cell Right-soft-covered cell

By assembling a single cell, the cells are formed into different series and parallel through the bus bar, which can be screwed, resistance welding, ultrasonic welding, ultrasonic aluminum wire welding and laser welding.

Taking into account the production yield, efficiency and internal resistance of the connection point, laser welding is currently the first choice for many battery manufacturers.

The composition of the PACK battery pack:

It mainly includes several parts of battery module, mechanism system, electrical system, thermal management system and BMS.

Battery module: If the battery pack is likened to a human body, then the module is the "heart" responsible for storing and releasing energy to power the car.

Mechanism system: It is mainly composed of battery pack upper cover, tray, various metal brackets, end plates and bolts. It can be regarded as the "skeleton" of the battery pack, which plays a role in supporting, resisting mechanical shock, mechanical vibration and environmental protection (waterproof and anti- dust).

Electrical system: It is mainly composed of high-voltage jumper or high-voltage wiring harness, low-voltage wiring harness and relay. The high-voltage wiring harness can be regarded as the "large artery" of the battery pack, which continuously transmits the power of the heart of the power battery system to each required component, while the low-voltage wiring harness can be regarded as the "neural network" of the battery pack, which transmits detection signals and control in real time. Signal.

Thermal management system: There are four main types of thermal management systems: air cooling, water cooling, liquid cooling, and phase change materials. Taking the water cooling system as an example, the thermal management system is mainly composed of cooling plates, cooling water pipes, heat insulation pads and heat conduction pads. The thermal management system is equivalent to installing an air conditioner on the battery pack.

BMS: Battery management system The battery management system can be seen as the "brain" of the battery. It is mainly composed of CMU and BMU.

CMU: Cell monitor Unit, which is responsible for measuring parameters such as voltage, current and temperature of the battery, as well as functions such as balancing. When the CMU measures these data, it transmits the data to the BMU through the battery "neural network" mentioned earlier.

BMU: Battery management Unit battery management unit. It is responsible for evaluating the data transmitted by the CMU. If the data is abnormal, it will protect the battery, issue a request to reduce the current, or cut off the charging and discharging path to prevent the battery from exceeding the permitted conditions of use, and also manage the battery power and temperature. According to the previously designed control strategy, the parameters and states that need to be alerted are judged, and the alert is sent to the vehicle controller, and finally conveyed to the driver.

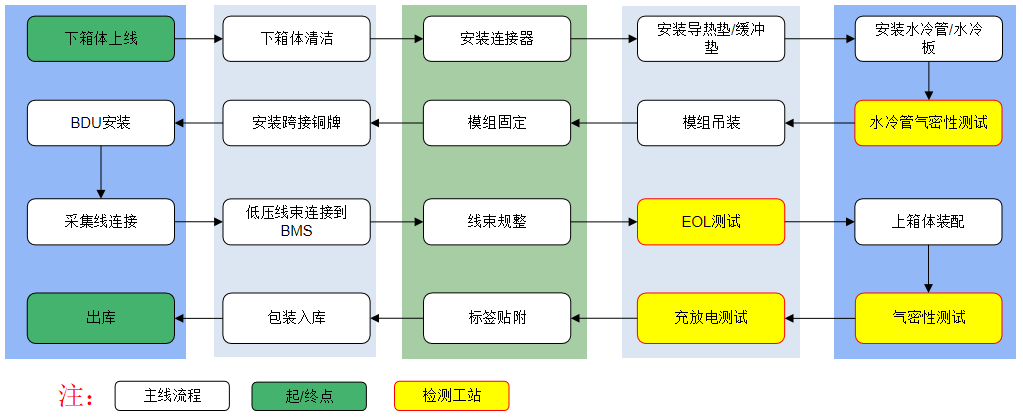

Process flow:

It is mainly divided into assembly process, air tightness detection process, software writing process, electrical performance detection process, etc.

The battery pack is the core energy source of energy vehicles, providing driving power for the entire vehicle. As the core component of new energy vehicles, its quality directly determines the performance of the whole vehicle. Lithium battery manufacturing equipment is generally divided into three types: front-end equipment, middle-stage equipment, and back-end equipment. The equipment precision and automation level will directly affect the production efficiency and consistency of products.

Although the types of cells and modules are different, the composition and process flow of PACK are generally the same (not all manufacturers have the same process flow). The following figure is for reference.

PACK assembly process flow

Production line introduction:

There are many flexible lines and press-fitting and tightening in the PACK assembly process. It is difficult to automate and the input-output ratio is not high. Therefore, the automation degree of the back-end equipment will be lower than that of the front and middle parts, but it is compatible. There are three types of PACK battery packs: cylindrical, square shell, and soft pack.

Work stations that may require automation:

-The lower shell is automatically online

-Module automatically goes online into the shell

-Module fixed and tightened

- Line and tighten the upper cover

- Automatically apply A/B thermal adhesive (depending on the process)

- Automatic application of sealant (depending on the process)

- Finished product offline

In addition, some will propose that the bronze medal installation and screw tightening, air tightness test, and EOL test also require automatic methods. This is relatively rare, and the stability is difficult to guarantee.

Summary: The above is the basic knowledge of lithium battery pack PACK.

As the development of the power battery industry gradually matures, the battery PACK modular technology will become more and more mature. The development of battery PACK technology involves multi-disciplinary and multi-field knowledge and requires interdisciplinary technology integration. All in all, if car companies want to finally produce PACK products on a large scale that fully meet the requirements of new energy vehicles in terms of lifespan, stability, reliability, and safety, they still need a lot of engineering practice and test verification, as well as continuous optimization and upgrading of products. process.

.png)